CROSSWELL STRAIN MONITORING

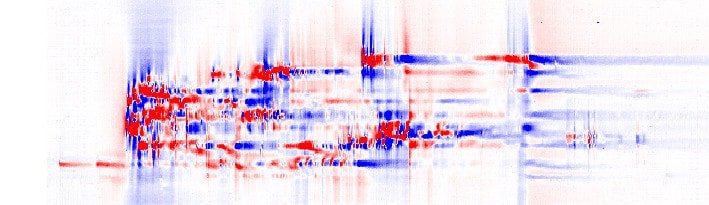

Fracture geometry information derived from Crosswell Strain frac hits provides a direct look into the efficiency of the treatment process. It critically reveals the nature and geometry of the fracture network and its development within the reservoir, indicating areas of enhanced production or areas with by-passed oil.

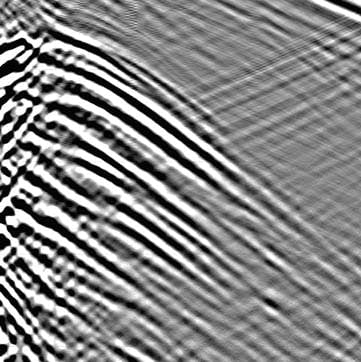

OptaSense’s dual stream data enables real time Crosswell Strain and Microseismic analysis for integral characterization of the fracturing processes. Full bandwidth Distributed Acoustic Sensing measurements, including rich low frequencies, allows the operator to understand not just the mechanical properties of the reservoir and its fractures, but also its fluids and their thermal responses seen by the same sensing fiber.

The Impact of Frac Hits on Production

A frac hit is an interwell communication event where an offset, or parent well, is affected by the pumping of a hydraulic fracturing treatment in a new well, call the child well. Depending on the distance between the parent and child well, a frac hit can be strong enough to damage production tubing, casing and even wellheads.

For older wells, frac hits can be especially detrimental. Reduced formation pressure allows frac hit reach that can impact production on the parent well, and in worst cases, permanently stop production after taking frac hits.

A Better Understanding of Your Formation

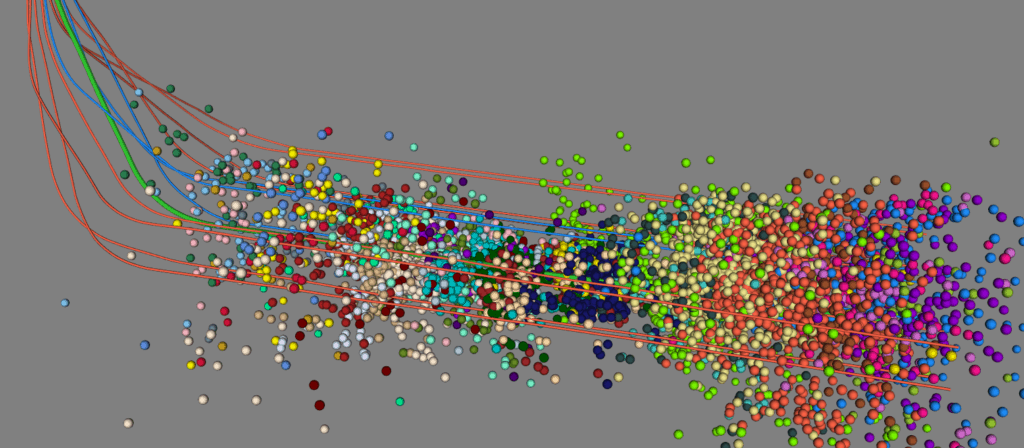

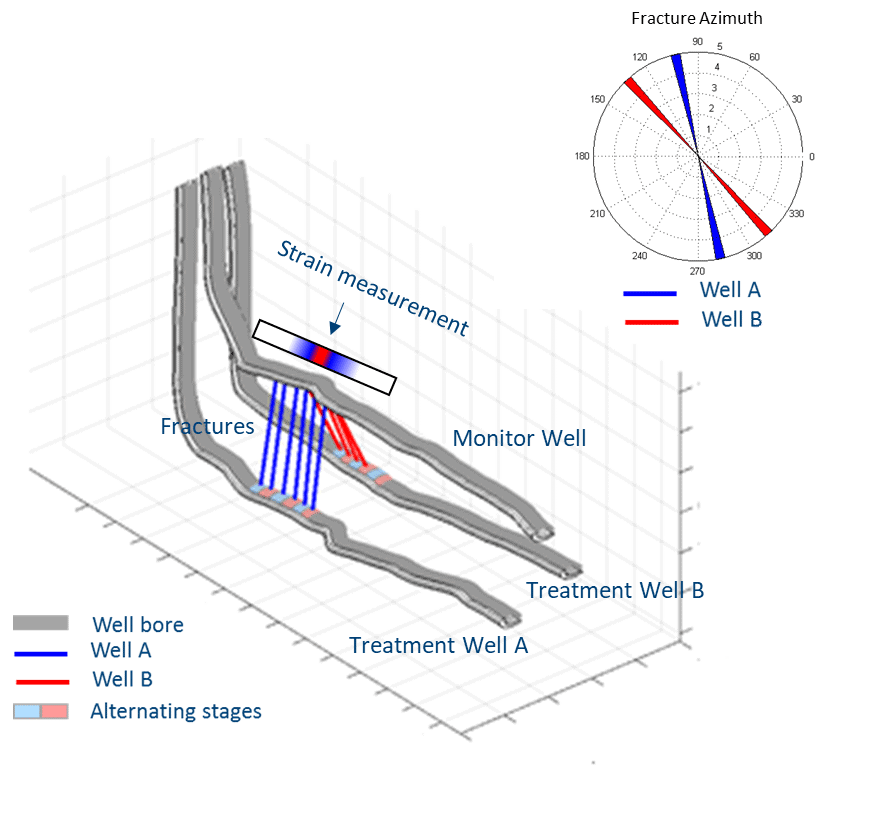

OptaSense’s Crosswell Strain Monitoring service measures the dynamic stress and strain changes within a rock formation from hydraulic fracturing stimulation and fracture growth attributed to hydraulic fracturing. From our low frequency distributed strain measurements, we can tell exactly how and where a fracture is propagating, uncovering key principles of a fracture’s orientation, length, growth rate and distribution. Fracture events communication locations and time can be captured from dynamic strain between the monitor well and treatment wells. Results are analyzed to evaluate the prescribed stimulation design, well positioning, fracture diagnostics and identifying geological controls and features.

High-resolution strain calibrated to the operator’s completion design.

Confident decisions can be made for optimized well spacing by evaluating how strain variations to the fracture program impact fracture driven interactions. With the ability to identify dominant fracture paths and fracture network in the reservoir, our clients are able to access parent-child well interactions. With this unique data set, subsequent wells can be better designed to target the intended treatment zone. OptaSense also delivers advanced analysis of the performance impact of various completion and stimulation techniques on quantitative reservoir dynamic strain level induced by fracturing treatment. This unique strain data enables detailed reservoir analysis to optimize completion and well spacing design.

Want to Optimize Your Completion Design?

A Better Understanding of Your Completion Design

High resolution Crosswell Strain measurements from OptaSense’s Distributed Acoustic Sensing Introgatorer Unit allows you to design the measurements based on your completion design. The ability to provide variable spatial resolutions allows the operator to optimally analyze the completion design and its performance and helps constrain operations based on complete high resolution data.

OptaSense Oilfield Services offers Crosswell Strain Monitoring on permanent or temporary deployed fiber cable. This exciting advent allows the sensing fiber cable to be deployed deep within the wellbore at a fraction of the cost of a permanent fiber cable, reducing planning and approval hurdles required for permanent fiber install and accelerating learning of reservoir exploitation. It also provides complementary analysis of far field fracture growth in addition to near field cluster distribution to enhance permanent fiber programs.

The OptaSense Crosswell Strain Monitoring service is agnostic to fiber type, cable type and partnering company. This allows us to provide greater geographical access and higher availability to monitor your wells.

Monitor multiple wells with one deployed cable.