COMPLETIONS MONITORING

OptaSense fiber-optic sensing technology provides key insights that allow you to optimize fracture program designs and mitigate operational issues while completing the well.

Completions Monitoring Services

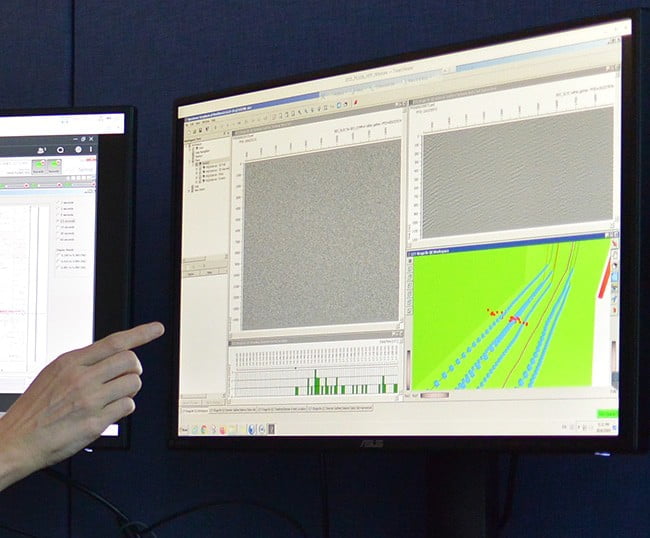

- OptaSense’s Hydraulic Fracturing Monitoring Services monitor stage completion and stimulation performance in real time at the perforation level.

- Diagnose the optimal completion design by assessing, in real time, efficiency and effectiveness while ensuring lowest treatment costs by analyzing fluid and proppant uptake volumes per perforation clusters.

- Assess operational issues of the treatment in real time. Identify inter-stage communication, wellbore integrity, and operational issues during fracturing treatment and provide fine details for in-time improvements.

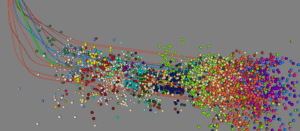

- Crosswell Strain Monitoring enables real-time assessment of fracturing treatment of multiple nearby wells with single permanent or temporary fiber deployment. This service uses the highest sensitivity and resolution far-field measurements of the stimulated reservoir volume (SRV).

- Optimize well spacing and reduce environmental risk by analyzing fracture initiation and fracture hit between the treatment well and the observation well.

- With dynamic pico-strain sensitivity, low frequency (LF) DAS is used to estimate fracture geometry and to determine stimulation effectiveness in the SRV.

Optasense’s interrogators record high-fidelity microseismic data coincident with other data streams. Having no moving parts means your array will never go down and full wellbore sampling ensures detected events are unmatched in their location accuracy. Microseismic monitoring from single or multi-well fiber acquisition enables the assessment of activity on a stage-by-stage basis to characterize stimulated reservoir volume.

Monitoring is achieved with one or more fibers installed permanently to casing, or on a temporary deployment via retrievable wireline. OptaSense’s intervention partners enable us to monitor any available wellbore with an optimal and more cost-effective deployment service.