CASE STUDY

Condition Monitoring of Power Cables for Offshore Wind Farm in Scotland

Reducing Costs in Real Time with Smart Sensing DAS Technology

Problem:

- Short circuit on main export cable

- Uncertainty on exact fault location

- Costly delays and offline power

Solution:

- OptaSense Integrated Smart Sensing Solution for Power Cables

- Real-time fault detection with +/- 10m accuracy

Value Delivered:

- Accurate fault location

- Repair made within 1 week

- Significant cost savings due to reduced downtime

The Challenge

While operating on an offshore wind farm in Scotland, midway between the Galloway and Cumbrian coasts, our client experienced a short circuit on a main export cable approximately 15km in length, of which 13 km was located subsea. Until the fault could be located and repaired, 80MW of offshore power would be sitting idle.

Existing Time Domain Reflectometry (TDR) methods using a high voltage pulse generator indicated the fault was 2km offshore. A repair in this location would cost the operator £8M, in addition to placing the wind turbines offline for up to 6 months—accruing a potential loss of revenue of £90,000 per day. The TDR technique is a manual and time consuming process to locate a fault. Even when operating well the accuracy of the TDR method is low (+/- 300 m on a 15 km cable).

The Solution

As with many export and inter-array subsea power cables, the export cable had an existing fiber-optic cable integrated within the structure — meaning the use of Distributed Acoustical Sensing (DAS) was possible.

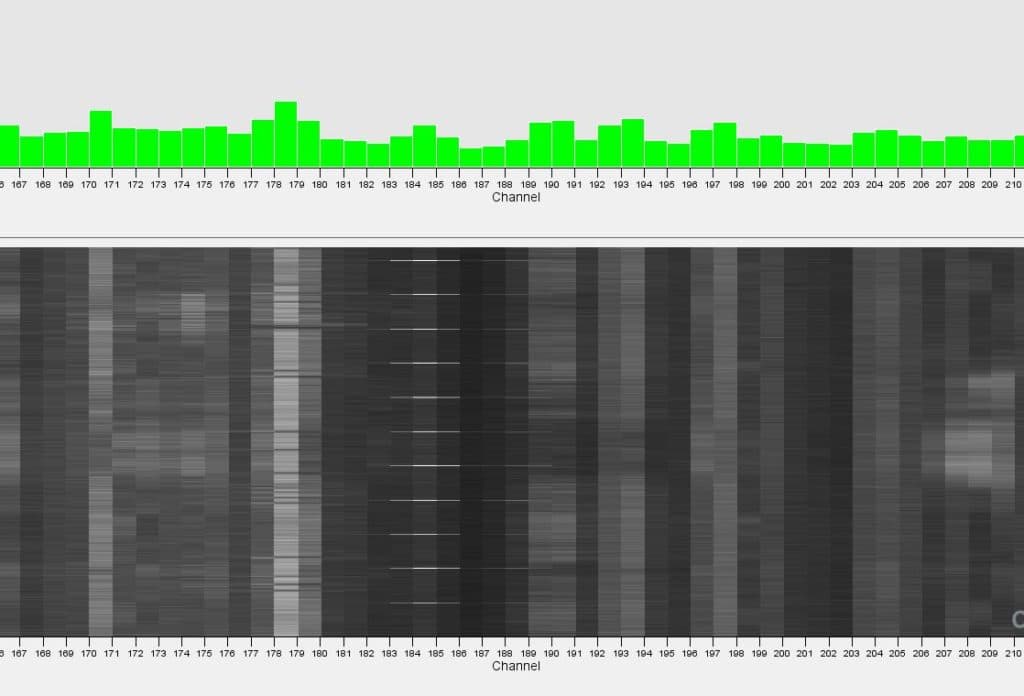

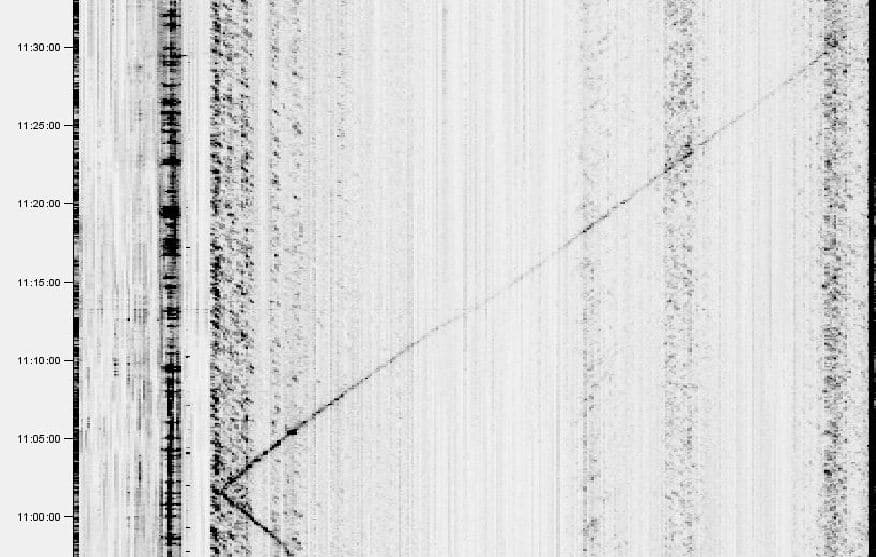

OptaSense DAS technology is a proven method for detecting any activity in the vicinity of an asset over long distances. Our DAS technology converts existing fiber-optic cables into an array of virtual microphones with no additional infield equipment required. Using this solution an operator is able to detect, classify and locate any breakdown or threatening events near to the assets in real time.

With the DAS cable already installed, OptaSense experts were able to mobilize quickly to access the site within 24 hours. In fact, the fault was located and verified within 4 hours of OptaSense arriving on site.

The location of the discharge noise, which was caused by the generator, was determined using the OptaSense interrogator unit. This interrogator unit was able to detect the fault in minutes, to an accuracy of +/- 10m. This accuracy allowed our experts to determine the fault was actually located on land, eliminating up to eight weeks of repair time at £10K per day and lost revenue for the operator. By identifying an onshore fault we additionally eliminated the need for high cost vessels and ROV’s.

Even though the fiber was located 2m away from the power cable, the OptaSense interrogator unit offers a long range capability of 40 km that allowed the fault to be easily and quickly detected onshore.

Results

After the fault location was confirmed, the operator completed repairs within a week. As a result of the quick turnaround OptaSense DAS technology enabled, our client realized a significant cost savings, when compared to traditional fault detection techniques.

With permanent connection of DAS technology, you enable instant fault location as well as analysis of other cable endangering situations, on or offshore.

Although there was no permanent DAS installed at the time failure occurred, OptaSense was able to leverage existing fiber to run DAS and locate the fault accurately in a relatively short time verses conventional methods that use TDR.

With a permanent OptaSense DAS installation, operators achieve 24/7 real-time monitoring, which enables operators to locate faults instantaneously at the time of occurrence rather than a few days later, saving time and money. The power utilities sector can benefit from DAS technology in various applications:

- Short circuit detection and localization; Identification of the fault such as short circuit and locate within 5 to 10 metres of occurrence for subsea and buried cables

- Protection against Third Party Intervention (TPI) for buried onshore and offshore cables

- Early detection with the ability to monitor in real time to detect, locate and alert. This provides the opportunity to intercept before an event occurs to safeguard the asset, such as the early detection of anchor drags, fishing nets etc

- Detect vortex induced vibrations and free scan in a cable (0.25-2.5Hz)

- Long measuring range per system up to 40km capability

For more information, please contact your OptaSense representative or visit optasense.com/power-utilities.