CASE STUDY

OptaSense Provides More Cost-effective Monitoring of Carbon Storage Facility

Saskatchewan, Alberta, Canada

Problem:

- Need for safe and cost-effective way to monitor permanent CO2 storage facility

- Lack of reliable, non-intrusive mapping tools

- High maintenance and deployment costs

Solution:

- OptaSense Distributed Fiber-Optic Sensing for CCS Monitoring

- CO2 plume mapping with active seismic data

- Injection monitoring

- Operational issue assessment

Value Delivered:

- Low cost, low intervention permanent monitoring of CCS facility

- High-sensitivity measurements for tracking migration of plumes

- 24/7 monitoring of operational and environmental risks due to injection

The Challenge

Increasing societal and environmental concerns have led the energy/utilities industries towards achieving zero carbon footprints while still providing reliable sources of energy. The availability of underground carbon dioxide (CO2) storage facilities is an important technological part of the future energy balance. The success of these facilities hinges on the proper storage and mapping of resources in reservoirs.

Monitoring these facilities has required diverse technologies that provide different diagnostics that can be difficult to integrate. Furthermore, as CO2 is injected into the subsurface, there is a need for low-cost solutions that can ensure that the materials are properly stored, hence requiring the need for constant monitoring.

An operator in Western Canada needed a cost-effective technology that would require the least amount of disruption to the storage facility and its wells in order to ensure that the materials were safely injected and stored underground.

The Solution

OptaSense’s distributed fiber-optic sensing technology was deployed in wells that were drilled to inject and store CO2 within a target formation. Using permanent instrumented wells provided a low-cost and minimal-intervention solution for long term monitoring.

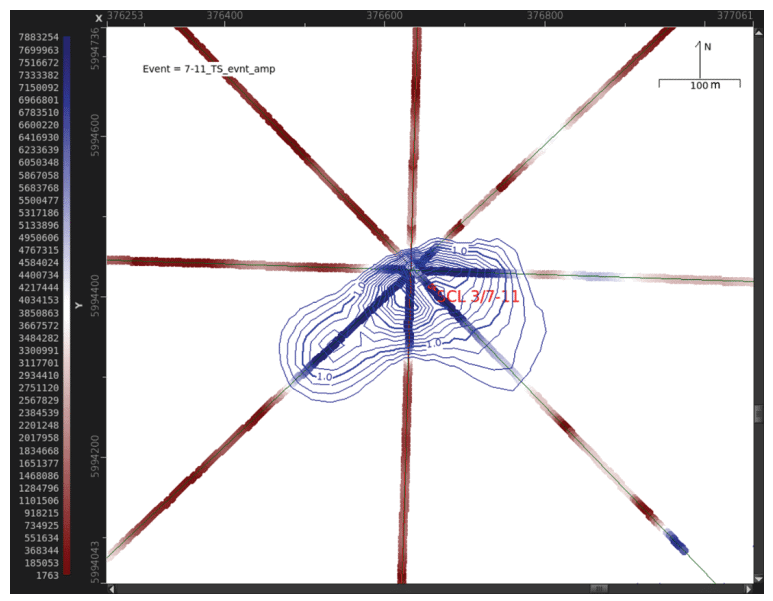

Minimum curvature interpolation of the amplitude difference between 2015 baseline and 2016 monitor in each VSP line, representing a map view of the seismic response to the presence of CO2 after 6 months of injection (Bacci, O’Brien, Frank, and Anderson, Using a Walk-away DAS Time-lapse VSP for CO2 Plume Monitoring at the Quest CCS Project, CSEG Recorder, April 2017, p. 21.)

The operator turned to OptaSense’s fiber-optic sensing for its ability to avoid additional well interventions as part of the monitoring. The use of distributed sensing technology was initially validated at a nearby facility to ensure that the fiber-optic sensing would provide sufficient resolution to detect and map the CO2 plume at different points in time after injection into the reservoir. At specific time intervals, active source seismic data was acquired using OptaSense’s Distributed Acoustic Sensing (DAS) technology. The various vintages of the data were compared against baseline measurements to provide a time lapse assessment of the migration of the plume.

OptaSense’s distributed sensing technology was deployed because of its high sensitivity and repeatability that would ensure that the subtle CO2 signatures could reliably be identified and mapped. Extensive project management and detailed field acquisition practices enabled the operator to obtain data in the least amount of time, while maximizing the value of conventional low-cost fiber-optic infrastructure.

The operator has been monitoring the facility more than five years using data from three wells acquired at near-yearly intervals. The success of the project has been dependent on OptaSense’s DAS systems which are highly portable and can operate within harsh environments, reducing HSE exposure to field and facilities personnel.

Delivered Value

The operator has been able to monitor the propagation of the CO2 plume within the storage facility. Information from the various DAS vintages showcase a repeatable technology that can successfully track small changes in the reservoir. They were able to validate their storage models with distributed sensing data, showing that these facilities can be effectively and safely monitored for years to come. By using fibers in the well or on the surface, the operator was able to avoid the high maintenance costs of other sensing instruments within a harsh well environment.

The use of distributed sensing also showcased the broad range of applications for the technology. The fiber measured data over a broad bandwidth and the measurements were shown to be sensitive to a range of physical phenomena including the movement and injection of fluids, seismic signals from active sources and seismic signals from passive sources like earthquakes or tides.

In July of 2020, the operator reached a milestone with the injection of five million tonnes of CO2 over a period of five years with a cost savings of 35% based on the original plan.

For more information, please contact your OptaSense representative or visit optasense.com/oilfield-services/carbon-sequestration-monitoring.