CASE STUDY

OptaSense Delivers More Cost-effective Solution for Monitoring Frac Hits

Real-time frac monitoring alternative to installed fiber

Problem:

- Need for better understanding of fracture

network between interwell spacing - Exact location of fracture network unknown

- No permanent installed fiber

Solution:

- OptaSense Distributed Fiber-optic Sensing

Solution- High quality DAS strain data on both

fibered wireline and coil - Cost-effective reservoir data acquisition

- Real time data streaming to evaluate

completions response within reservoir - Better understanding of frac height

growth between the different Montney

layers

- High quality DAS strain data on both

Value Delivered:

- Real-time monitoring of frac strain events

- Effective alternative to permanent

installed fiber - Cost savings from elimination of

additional rig time

The Challenge

A Canadian oil and gas producer completed a nine well pad with all wells landing in the Montney Formation in British Columbia. They wanted to gain a better understanding of their completions program through various monitoring technologies in order to help optimize and increase efficiency for future programs. To aid in the completions monitoring, they wanted to incorporate various complementing technologies to build and further refine their regression analysis and numerical modeling.

The operator faced several challenges in monitoring their completions. They needed to better understand the fracture network between the interwell spacing. Pressure gauges at surface are typically used to capture frac hits on neighboring wells, which in turn can be used to understand frac geometry and connectivity within the reservoir. However, this approach has its limitations such us knowing the actual fracture network location within the reservoir and its relative location to the treatment well. The other challenge faced by the operator was that the wells had not been completed with a permanent fiber-optic installation. The operator needed a cost-effective solution that allowed them to acquire the reservoir information they needed without the need for permanently installed fiber.

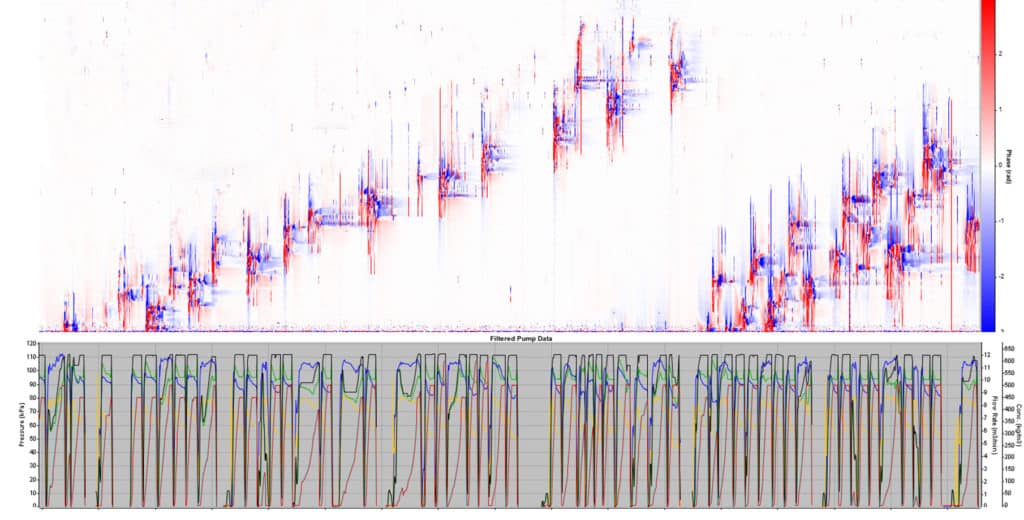

Crosswell strain DAS of entire frac program collected on deployed wireline in a neighboring well. Waterfall DAS data and completion pump curves displayed.

The Solution

The Optasense distributed fiber-optic sensing solution was selected by the operator to monitor their completions program. OptaSense can acquire high quality DAS strain data on fibered wireline and/or fibered coil. This ability to acquire frac strain data on a deployable fiber provides a cost-effective solution for any operator and still provides the reservoir characteristics used in refining models and other analytical workflows.

OptaSense’s ODH4+ interrogator unit was used for the acquisition and its industry-leading strain analysis workflow was utilized for the answer product. Fiberoptic microseismicity did a better job of detecting and highlighting more regional and structural related microseismicity compared with geophone microseismicity.

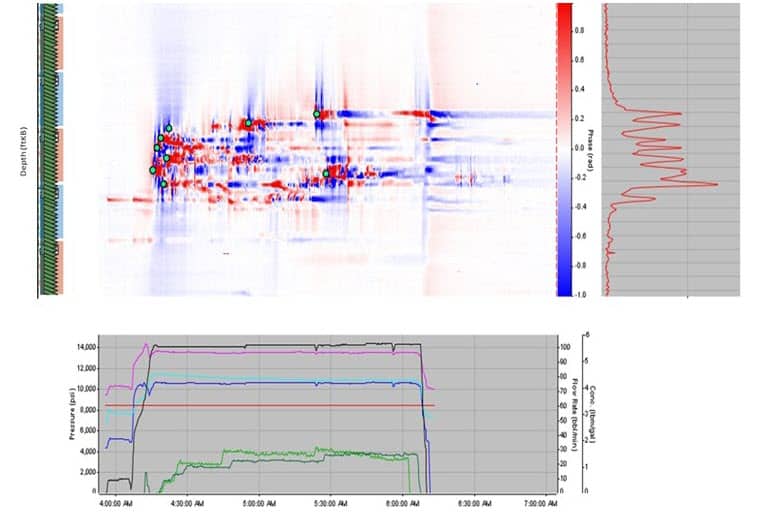

Example of a single stage DAS crosswell strain event captured from fiber deployed on wireline. DAS waterfall, summed strain, wellbore diagram, and completions curves displayed.

Delivered Value

Once the OptaSense solution was applied, the client was able to acquire real-time monitoring of the frac strain events. The fiber-optic deployable solution is just as robust and provides similar solutions in understanding the interwell fracture characteristics compared to a permanent fiber solution. There was also a significant cost savings to the client as there was no additional rig time during the completions of the well.

For more information, please contact your OptaSense representative or visit www.optasense.com/oilfield-services/crosswell-strain-monitoring