CASE STUDY

OptaSense Achieves Perfect Score On Gas Utility Damage Prevention Testing

Monitoring System Excels at Detecting and Classifying Events

Problem:

- Third party intrusion and damage to natural gas distribution pipelines

- Costly nuisance alarms

Solution:

- OptaSense Pipeline Threat Monitoring System:

– Detects and locates suspicious activity Advanced analytics recognizes routine activity reducing nuisance alarms

Value Delivered:

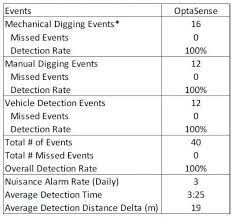

Blind testing results:

– Mechanical digging detection rate – 100%

– Manual digging detection rate – 100%

– Vehicle detection rate – 100%

– Average detection time – 03:25 minutes

– Average detection distance – 19m

– Nuisance alarms limited to less than 3 per day

Project Overview

The natural gas industry is constantly seeking new or enhanced techniques to address the issues of third party intrusions and damage to their distribution pipelines. The majority of techniques in use to monitor pipelines use an approach (e.g. aerial survey over the pipeline) where the system is assessed on a periodic basis resulting in an instantaneous view or “snapshot” of the system to detect intrusions.

An alternative to this approach, Distributed Fiber Optic Sensing, has become more technically and commercially accepted as pipeline owners have come to see it as an effective and efficient real-time monitoring solution.

A national gas utility sought to rigorously test the benefits associated with this damage prevention technology as part of a commercial deployment, running a number of blind tests of right of way threats.

Additionally, because a number pipelines are located along roadways and right of ways, significant numbers of nuisance alarms can occur, resulting in unnecessary manpower costs and downtime.

The Solution

A project was initiated that focused on installing and evaluating the performance of the OptaSense fiber-optic threat detection system on a 2.5 km long section of a gas distribution pipeline.

In preparation for blind testing of the system, a threat profile was created for the length of the pipeline that was to be monitored by the fiber-optic system. This allowed for specific tuning of the system, which would potentially reduce the nusiance alarms while enabling threat detection.

Two specific sections of the pipeline were identified – the first representing vital mains in urban locations and the second representing government-regulated pipelines in rural locations. In order to test the system, specific “events” were identified and selected, including mechanical and manual digging, pipeline activity, and vehicle activity.

The OptaSense pipeline threat detection system is designed to collect event data and as each event is detected, it is analyzed and categorized using system algorithms. With the system, it is possible to observe events in real time as they happen.

The system provides alarms at three separate levels, low, medium and high. This is a very useful feature because all high-level alarms start as low level detections and progress from low to medium and then to high level, where an alarm is generated and issued according to the designated system communicating parameters selected by the operator. This enables the operator to monitor an event condition that exists along the pipeline at a particular moment in time. This can provide advanced notice dispatching of personnel to investigate unauthorized activity.

For the test, forty unscheduled and random excavating and activity events were conducted over a three-day period in the monitored sections along the pipeline. Blind testing was conducted under closely monitored conditions. The time of the event was noted as well as the GPS coordinates for the equipment location, be it a backhoe, or simply a person digging with shovel. Using the alarm reporting logs from the OptaSense system, the event was identified in the alarm log. If detected and an alarm generated, it was then synchronized with the field data recorded.

Summary of the blind test results. Mechanical digging included a horizontal directional drilling rig, a backhoe and a mini excavator.

Delivered Value

Based on the results of the blind testing, the overall detection rate calculated for the OptaSense system was 100%. The average detection time was three minutes and twenty-five seconds and the detection distance was up to 19 meters from the pipeline.

An investigation into nuisance alarms was completed in order to determine if there are specific locations along the test pipe- line that are susceptible to erroneous sound levels that result in repeated alarms. It was found that the section of the pipeline that runs along the side of a compressor station was prone to repeated nuisance alarms. OptaSense developed a specific algorithm that identified the acoustic signature associated with this section of the pipeline and incorporated it into the operation of the system. As a result, nuisance alarm rates were found to be acceptable and manageable by the operator.

Based on the blind test results, the OptaSense pipeline threat monitoring system excelled at detecting mechanical excavating, manual digging, vehicle and general activity.

For more information, please contact your OptaSense representative or visit optasense.com/pipeline-monitoring.